Inner and central tracking with PID (Straw Chambers)

WP Leader:

• Peter Wintz

Contact: DRD1-WP3-leaders@cern.ch

Participating institutes:

Georgian Technical University (GTU) and Institute of quantum physics and engineering (IQPE), Tbilisi, Georgia

Forschungszentrum Jülich GmbH (FZJ), Germany

Gesellschaft für Schwerionenforschung GmbH (GSI), Germany

Hamburg University, Germany

Max-Planck Institute for Physics (MPP), Garching, Germany

Ruhr-Universität Bochum (RUB), Germany

IIT Guwahati (IITG), Guwahati, India

IIT Kanpur (IITK), Kanpur, India

NISER (NISER), Bhubaneswar, India

University of Delhi (U Delhi), Delhi, India

Punjab University (U Punjab), Chandigarh, India

Torino section of INFN and Università degli studi di Torino (INFN-TO), Italy

Institute of Nuclear Physics (INP-Almaty), Almaty, Kazakhstan

Jagiellonian University, Krakow (JU Krakow), Poland

Horia Hulubei National Institute of Physics and Nuclear Engineering (IFIN-HH), Bucharest, Romania

European Organization for Nuclear Research (CERN), Switzerland

University of South Carolina (U South Carolina), Columbia, SC, USA

Duke University (U Duke), Durham, NC, USA

US Cluster

(Brookhaven National Laboratory, Florida Institute of Technology, Jefferson Lab, University of Massachusetts Amherst, University of Michigan, University of California Irvine, University of Wisconsin-Madison, Tufts University), USA

DESCRIPTION OF THE WORK PACKAGE

Straw chamber and drift tube technologies are widely used in particle physics experiments and can cover a broad range of future applications from high-energy physics (HEP) and hadron physics at future accelerators (e.g. FCC-ee, CEPC, FCC-hh, FAIR) to Dark sector, rare event searches and neutrino physics experiments. An application-specific optimization of straw chamber technologies is required including the development of straw tube and detector designs, materials, production techniques, electronic readout with ASIC design, prototype or demonstrator setups with test measurements. Software algorithms for data analyses and simulation in parallel will be developed. Various simulation software packages and frameworks will be used for the mechanical detector and electronics designs and further developed.

Main straw specifications are the wire and tube material, tube diameter and wall thickness, straw length, end-cap design and electric contacting, gas mixture and the straw signal measurement information registered by the electronic readout. The front-end electronics (e.g. ASIC design) and readout system must be developed taking into account particle rates and timing requirements. In addition to the straw signal time for the spatial track information, the measurement of the particle-specific ionization (dE/dx) can be used for particle identification (PID) in the lower momentum region.

The optimization of straw tube materials focuses on thin films with less than 30 μm and less than 20 μm (maybe 12 μm) thickness to reduce the radiation length of a straw to below 0.02% (X/X0). Then, the contribution from the tube wall is comparable to the gas volume (for a 10 mm tube diameter and 2bar absolute gas pressure). Different types of metallization of such thin films will be investigated with respect to high particle rate capability (up to 1 MHz/tube), improved ageing and corrosion resistance, and low cross-talk between adjacent tubes. High purity and ageing resistance of all materials are mandatory to extend detector longevity. Tube diameters of 20mm, 10mm, and 5mm will be studied, the latter for fast timing (< 80ns) and high particle rates up to 50kHz/cm2. The assembly of thin-wall straws with up to 5m length will be developed. New straw production technologies include assembly techniques, all tools, and definition of quality assurance (QA) methods during the production steps, important for future experiments requiring series production of hundred-thousands of straw tubes.

The mechanical detector system has to support and precisely align the straws with up to 5m length. Such ultra-long straws require innovative mechanical support techniques, like carbon- fibre suspension, constant-force springs or self-supporting cemented packs of straws. The use of very thin straw films for minimal material budget requires R&D on the film properties under mechanical stress and over a long time to investigate long-term material relaxation and creeping and develop methods for compensation. A unique application of straw detectors is their operation in surrounding vacuum due to their robust mechanical shape if the gas inside the thin film tubes is at over-pressure of about 1bar. This technology allows very large detection areas (~ 50 m2) together with thin foils (< 30 μm) in vacuum. The control of gas leakage and change of the gas mixture ratio by a difference in the molecular permeation through the thin film wall are key aspects.

Various prototype straw and drift tube detectors will be set up with electronic readout consisting of new, custom-specific designed ASICs. ASICs for time and charge readout and for high or moderate particle rates will be developed. A demonstrator inner tracking straw detector consisting of 10mm diameter tubes arranged in about 20 close-packed layers will be built to perform and optimize 4D+PID track measurements (3D-space, time t0, dE/dx). The dE/dx information by the signal time-over-threshold will be used for particle identification (PID) in the lower momentum region. The 4D+PID track reconstruction and detector alignment software algorithms will be developed including simulation and data analysis.

Part of this work package is the set up of a new straw series production facility (at INP Almaty) with the technique of ultrasonic welding of thin film tubes of different diameter, different film tube thickness, and lengths up to 5m and including quality control procedures. This contribution is very important for this work package, but might also be of benefit for the whole straw detector community in future.

Relevance in context of ECFA Roadmap

The work package covers the following DRD themes (DRDT) which have been defined by the ECFA Detector R&D Roadmap Process Group. CERN-ESU-017. CERN, 2020, p. 248. DOI: 10.17181/CERN.XDPL.W2EX

-

DRDT 1.1 - Improve time and spatial resolution for gaseous detectors with long-term stability.

-

DRDT 1.2 - Achieve tracking in gaseous detectors with dE/dx and dN/dx capability in large volumes with very low material budget and different read-out schemes.

-

DRDT 1.3 - Develop environmentally friendly gaseous detectors for very large areas with high-rate capability.

Tasks

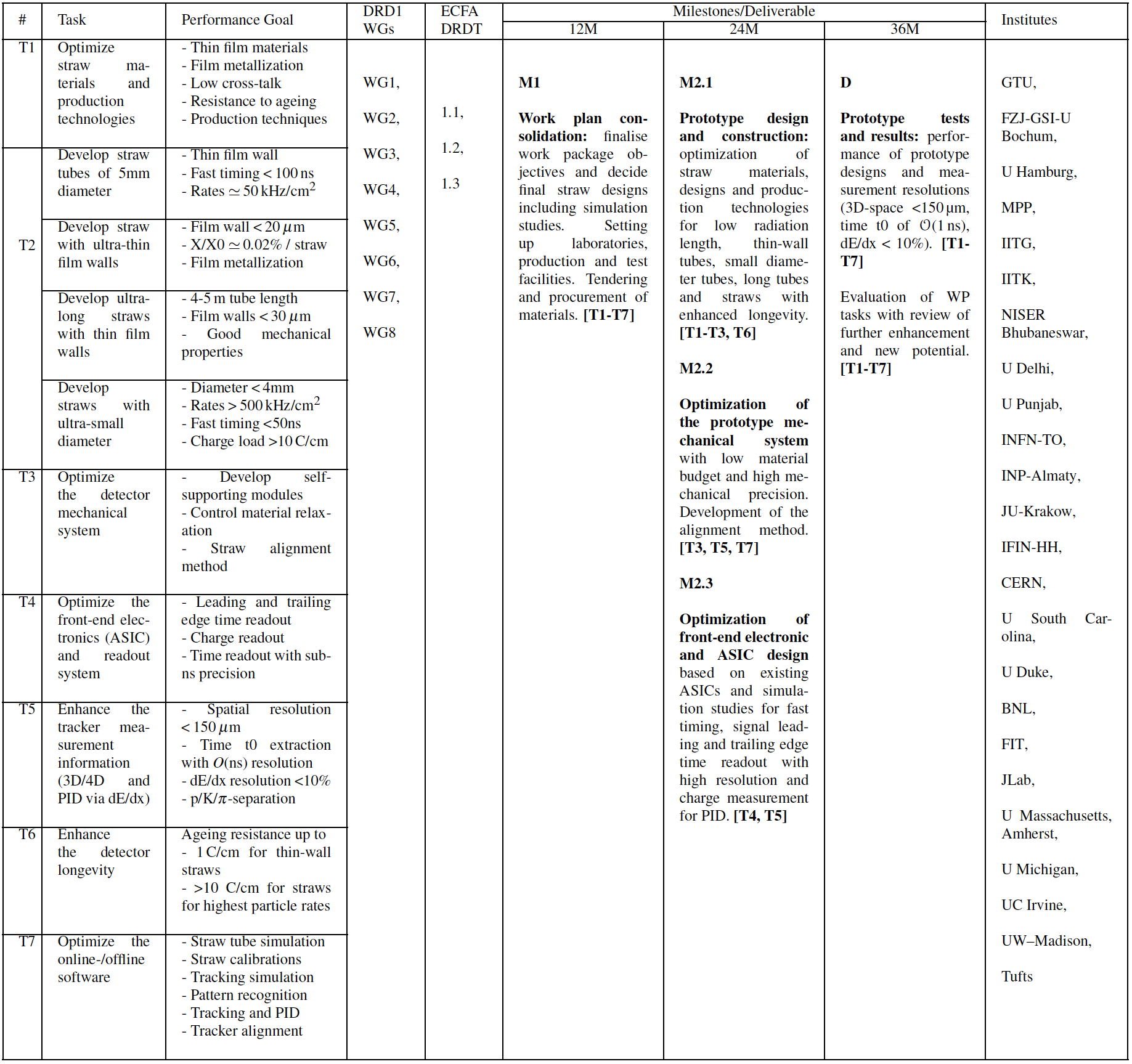

The R&D topics in this work package consists of seven tasks.

-

T1: Optimize straw materials and straw production technologies

-

T2: Improve straw tube designs

-

T2a: Straw tubes of 5mm diameter

-

T2b: Straws with ultra-thin film wall

-

T2c: Ultra-long straws (up to 5m)

-

T2d: Straw tubes with < 4mm diameter

-

-

T3: Optimize the detector mechanical system

-

T4: Optimize the front-end electronics (ASIC) and read-out system

-

T5: Enhance the tracker measurement information (3D, t0, dE/dx)

-

T6: Enhance the longevity of the detector

-

T7: Optimize the online-/offline software

Work package organization

The work package is organized in work projects, which address certain R&D aspects for the respective application, but also the formation of collaborating sub-groups and common project description for funding application.

The first four projects (A-D) refer to drift tube and straw chamber technologies for applications at future accelerators, including also non-HEP applications, like Dark Sector and neutrino physics experiment installations. Projects E and F have a more general approach.

-

Project A - Drift tube developments for new high-rate applications

-

Project B - Straw chamber technologies for hadron physics applications

-

Project C - Large area straw detector for Dark Sector applications

-

Project D - Straw chamber technologies for neutrino physics applications

-

Project E - Optimization of straw materials and production technologies

-

Project F - Optimization of electronic readout

Each project contains a detailed R&D description, list of dedicated tasks, deliverables and timelines.