Inner and central tracking with PID (Drift Chambers)

WP Leader:

• Nicola De Filippis

Contact: DRD1-WP2-leaders@cern.ch

Participating institutes:

Laboratoire de Physique des 2 Infinis Irène Joliot-Curie (IJCLab-IN2P3) INFN, Bari (INFN-BA) INFN, Lecce (INFN-LE) INFN, Rome (INFN-RM) US cluster (US) Nankai University (Nankai U.) Tsinghua University (Tsinghua U.) Institute of High Energy Physics, Chinese Academy of Sciences (IHEP-CAS) Wuhan University (Wuhan U.) Jilin University (Jilin U.) University of Science and Technology of China (USTC) Institute of Modern Physics, Chinese Academy of Sciences (IMP-CAS) Bose Institute (Bose)

DESCRIPTION OF THE WORK PACKAGE

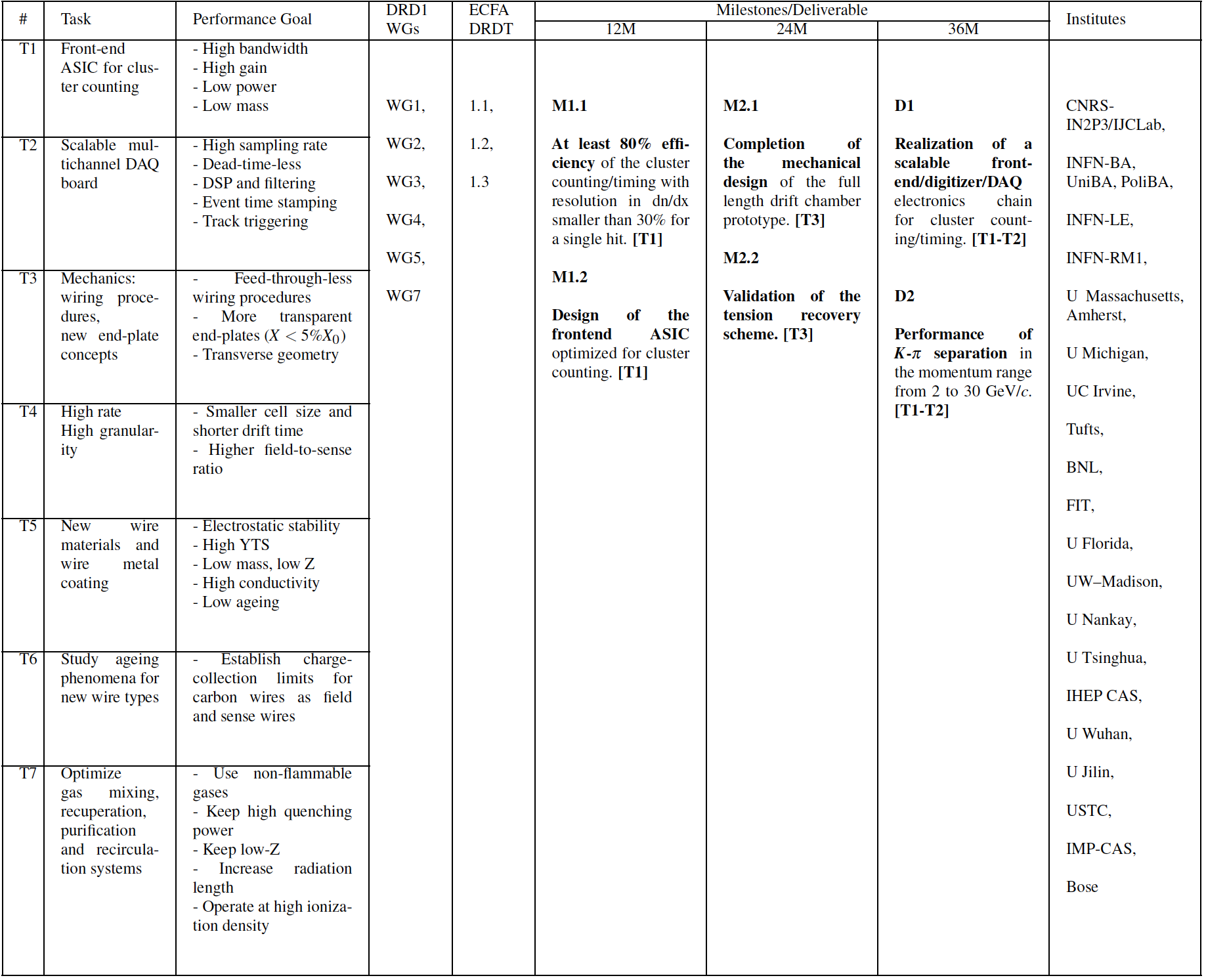

The project aims to cover strategic R&D towards the development of large-volume drift chambers proposed as tracking and particle identification devices for the next generation of lepton colliders both at FCC-ee (CERN) and at CEPC (IHEP China). Analogous proposals exist for the next generation of flavor factories SCTF (Russia, China) and could easily be adapted for Electron-Ion Colliders. Drift chambers provide high-precision tracking even at low transverse momentum thanks to the high transparency, and excellent particle identification by profiting from the cluster counting information. Key aspects for the R&D challenges are related to the mechanics, the electronics and the choice of gas mixture.

TASKS AND DELIVERABLES

T1: Development of front-end ASIC for cluster counting

- D1.1: Full design, construction and test of a first prototype of the front-end ASIC for cluster counting

T2: Development of a scalable multichannel DAQ board

-

D2.1: Working prototype of a scalable multichannel DAQ board

T3: Mechanics: new wiring procedures and new endplate concepts

-

D3.1: Conceptual designs of novel wiring procedures.

-

D3.2: Full design of innovative concepts of endplate

T4: Increase rate capability and granularity

-

D4.1: Performance on prototypes of drift cells at different granularities and with different field configurations

T5: Consolidation of new wire materials and wire metal coating

-

D5.1: Construction of a magnetron sputtering facility for metal coating of carbon wires

T6: Study ageing phenomena for new wire types

-

D6.1: Tests of prototypes built with new wire types at beams and irradiation facilities.

-

D6.2: Measurement of performance and dependence on total integrated charge

T7: Optimization of gas mixing, recuperation, purification and recirculation systems

-

D7.1: Performance of hydrocarbon-free gas mixtures full

-

D7.2: Design of a recirculating system